Contents

- Index

Cpk

Capability index measuring the ability of the process to meet the specifications. Both variation and centering are considered. One way of writing its formula is:

where USL is the upper specification limit, LSL is the lower specification limit, m is the average and s is the standard deviation. If only one specification limit exists, calculate only that part of the equation and omit the minimum. Cpk is independent of the units of measure.

So long as Cpk is 1.5 or greater, no more than 3.4 defects per million will result. If statistical tolerancing is being applied, one should strive for a Cpk of 2 at target. This ensures Cpk is above 1.5 so long as the process remains close to target. If process tolerancing is being applied, one should strive for a minimum Cpk of 1.5. This ensures no more than 3.4 values per million exceed the specifications. This level of defects is called Six Sigma Quality.

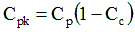

Cpk is always less than or equal to Cp. They are equal only if the process is perfectly centered. A poor Cp value indicates a variation problem. An acceptable Cp but poor Cpk indicates a centering problem. When there are two spec limits and the target is mid spec, Cpk can be written in turns of Cp and Cc as follows: