Contents

- Index

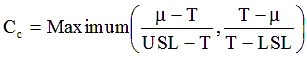

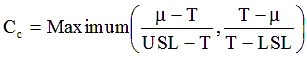

Cc

Capability index comparing the process average with the target and spec. limits to assess the centering of the process. Its formula is:

where USL is the upper specification limit, LSL is the lower specification limit, T is the target and m is the process average. Cc is independent of the units of measure.

A value of 0.25 means the average is in the middle quarter of the spec. A value of 0.50 means the average is in the middle half of the spec. Unlike Cp and Cpk, smaller values of Cc are better. Ideally a Cc of 0.25 should be obtained. This in combination with a Cp of 2 results in Six Sigma Quality.

Cc can only be calculated in the event of two specification limits and target. Cc does not consider the process variation. Variation is evaluated using Cp and Cpk.